Forklift Security

Because a forklift is a rear-wheel-drive, it makes it very hard to make fast quits, so never drive rapid or rounded edges too quickly. Never ever offer the steering wheel a sharp crank when driving at any speed. tracks and also never ever attempt to open railcar doors with the forks.

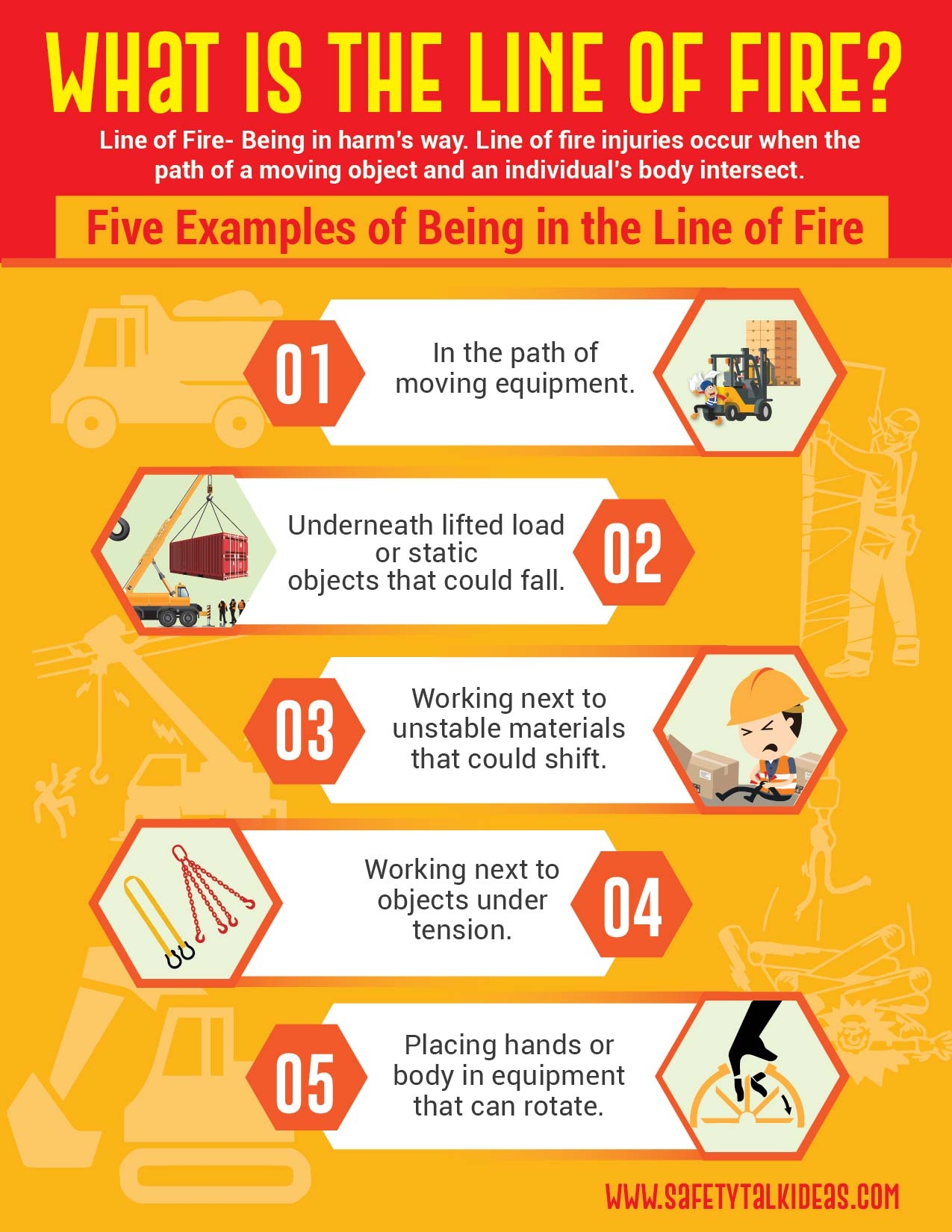

Making use of the correct devices for the job handy is vital to keeping your workplace accident cost-free. There are a variety of various forklifts for different demands, and it is safety moment crucial to make use of the right lift for the best task. For instance, trying to make use of the average forklift in a tight room can result in mishaps and knocked stacks of stock. Similarly, making use of a smaller sized forklift for a heavier load can cause slippage and also cause gone down supply, which can threaten workers. Never ever have a worker ride on the lift section of a forklift, as well as see to it that every employee recognizes the existence of the forklift by utilizing the safety lights.

Understand The Forklift Class

In Number 14, the center of gravity is in between the axle of the guide wheels at An and the drive wheels at B-C as well as it is noted with the arrow as the Lorry Center Of Mass. Notice the center of mass of the lots and also truck system change forward toward the front wheels as the tons is engaged.

Forklift safety avoids instant dangers to on your own and also various other workers operating in your location. Motorists that run forklifts with correct forklift training will protect against, or perhaps minimize crashes from happening at work website. Lastly, remain sharp as well as work at a safe rate; sidetracked or rushing employees as well as quick paced forklift driving can cause a crash or injury. Obtain routine training on forklift safety to bear in mind secure work techniques and also the effects if you do not follow them.

Know the ability of your forklift and any kind of attachments utilized.

In addition to seating yourself securely, take the complying with steps before running the forklift to enhance your safety and security.

Before using a forklift, ensure your hands and also shoes are completely dry as well as being in a comfy position with all the controls accessible.

Prevent hauling weight that exceeds the counterweight of the forklift.

Because lots of accidents are because of poor training, it is suggested that only those who have actually been educated and also accredited based on OSHA standards be responsible for running a forklift.

Execute Solutions For Forklift Safety

Before starting job make certain that a comfortable operating placement is found and all controls are within simple reach. The armrest, seat setting as well as mirrors must be appropriately readjusted and also the safety and security belt ought to always be attached. A lot of forklift accidents which include pedestrians take place due to the fact that the pedestrian simply did not see the forklift coming or due to the fact that the forklift driver did not see them approaching. Blind corners are usually at fault, as are loud sounds or plain old interruption.

Frequently inspect the lift top to bottom to search for anything that is out of the common. This includes any kind of loosened or broken wires, loose or broken pipes, fluids on the flooring, weird noises, scents, or smoke, plus anything else uncommon. Overturns, collisions, as well as various other severe failings can cause casualties. Using caution, complying with the customary practices, as well as driving the the tons in the appropriate position can prevent serious injuries as well as also fatality. Whenever possible, maintain the blades low, even when there is no tons. If a mishap occurs entailing an individual when the blades are low, the individual's legs will certainly probably be wounded. If the blades are high, you can lance someone's breast or abdominal area and also kill them.

There are commonly other drivers, pedestrians, and also co-workers within close area of an operating forklift. Forklift drivers drive around forklifts moving materials in busy areas including storage backyards, factories, as well as storehouses. With an efficient forklift safety approach called "Program Your Hands". When the forklift motorist sees any kind of pedestrian they ought to hold up their hand in a freeze frame. The pedestrian needs to keep an eye out for hand signals; if they see the hand signal they are too close. Forklifts are so hefty as well as powerful that also the tiniest bump from a forklift can send a pedestrian flying. Take duty for your own security and also for the pedestrians around you today.

This category only consists of cookies that guarantees fundamental performances and security attributes of the website. We use cookies on this website to enhance your experience and also to understand just how people use our website. These steps must be followed regardless of the length of time an operator prepares to be away from their lorry. neutral setting, and the forks are lowered to ground level. Never ever try to turn a forklift around when not on degree ground.

These powered industrial trucks are made use of to raise and carry lots with deft and accuracy. Although forklifts are effective, there is risk involved in operating any type of industrial maker. With over an estimated toolbox com safety one million forklifts estimated to be in procedure, it's necessary to make certain crews are trained on proper precaution. When a lots is placed on a forklift, the key concept is the mixed center of mass of the forklift as well as the tons. The heavy counterweight situated towards the rear of the forklift positions the center of mass toward the back, which maintains the forklift from tipping forward. In the meanwhile, a 4,000 extra pound load including a dice with also weight circulation has a CG in its facility. Yet if the tons is too heavy, or if it is put at the end of the forks to ensure that the tons facility range is increased, the excessive lots minute will certainly create the forklift to tip forward.

While examining a workplace environment for forklift threats, make Discover more here sure to plainly note locations the forklift could diminish, knock down aisles or otherwise trigger damage to firm building. That stated, 29 CFR 1910.144-- the company's criterion for laying out safety color codes-- points out that red and yellow are designated safety and security shade codes for noting physical threats.

Last updated